PhD Candidate in Engineering Science

Department of Mechanical Engineering, PMA division

KU Leuven

Shuhao Zhang obtained the B.S. degree in electromechanical engineering from the University of Macau in 2018, and the M.E. degree in mechatronics from the University of Melbourne in 2020. His master thesis focused on optimization-based collision avoidance and nonlinear model predictive control of multiple autonomous vehicles. His research interests include optimal motion planning and control of multi-agent systems, and learning-based optimization and control of robotic systems under uncertainties.

Project description

The European manufacturing industry is trending towards the production of highlycustomized complex products in small quantities, for which a flexible production system is key to be cost-effective. Flexible automation demands robotic systems such as mobile platforms and serial manipulators to perform multiple and highly complex tasks in unstructured and uncertain environments, hereby involving extensive sensing such as vision and force, and learning on-the-spot through active sensing. MPC holds great potential for controlling such systems since they are characterized by highly nonlinear and coupled dynamics as well as hard operational constraints.

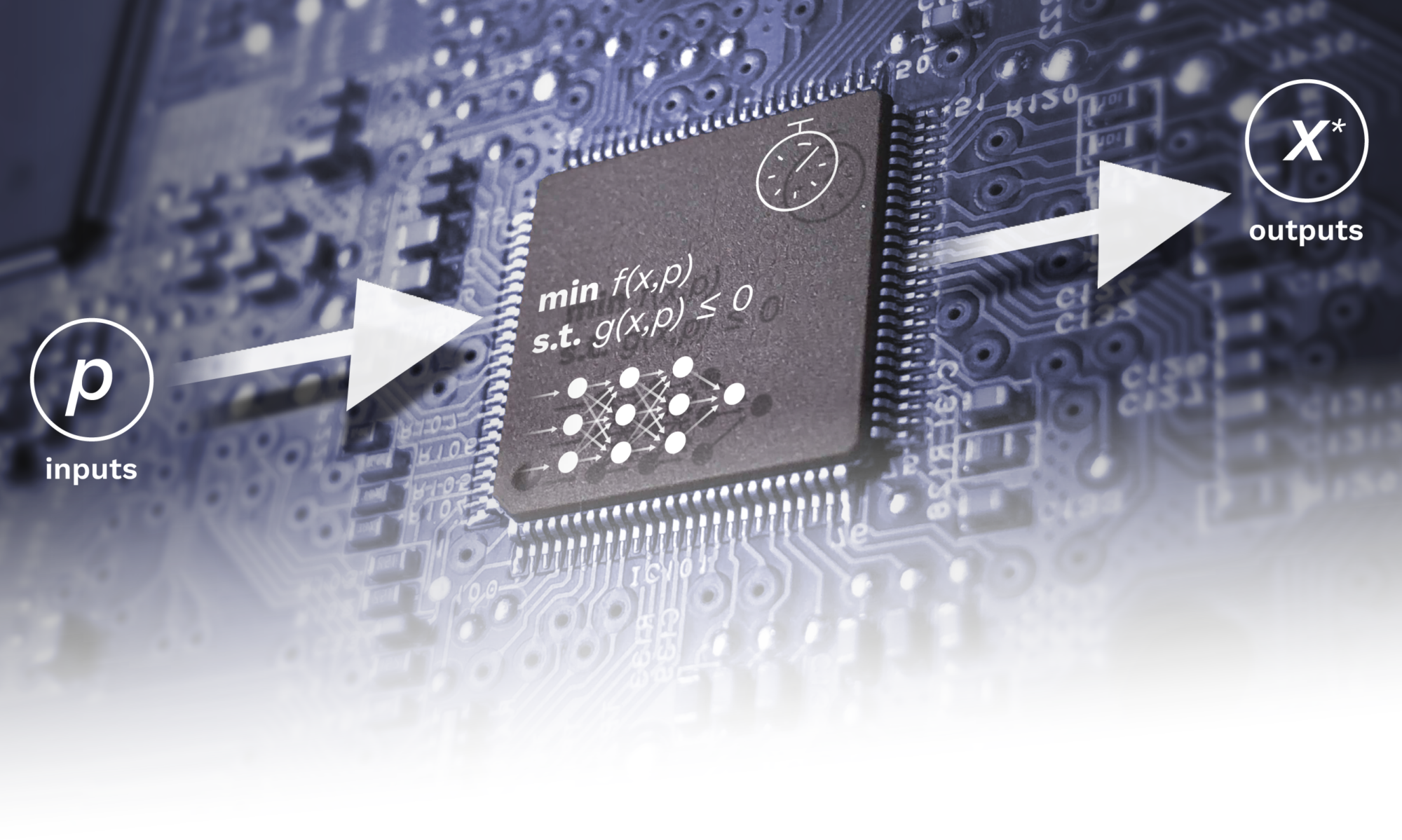

The overall goal of this project is to develop optimisation-based control approaches that increase the performance and flexibility of robotic systems. The first objective is to develop appropriate robot models and tailored embedded optimisation algorithms that are capable of solving the highly nonlinear optimisation problems arising in robotics MPC at a rate in the range of 100-1000 Hertz.

The second objective is to effectively deal with uncertainties: MPC will be merged with active-sensing strategies to learn properties of the environment and reduce uncertainty in the environment while executing the task, and augmented with risk-averse policies to handle the remaining uncertainty. The third objective is to embed the control algorithms in an automated tool chain that facilitates the robot (re)programming for different tasks. In flexible automation, the programming effort is a major cost factor and it is decisive to the economic viability of a robot application.