PhD Candidate in Information Technology – Systems and Control

Dipartimento di Elettronica, Informazione e Bioingegneria (DEIB)

Politecnico di Milano

Nicolas Kessler graduated in mechatronics at Karlsruhe Institute of Technology in 2021 with focus on software engineering and control theory. Originally born in Germany, he also lived in France and China. During his studies he participated at Kamaro Engineering e. V. working on modular field robots. His Master thesis was on the modeling of the space maneuvering and docking vehicles at the test facility at University Würzburg.

Project description

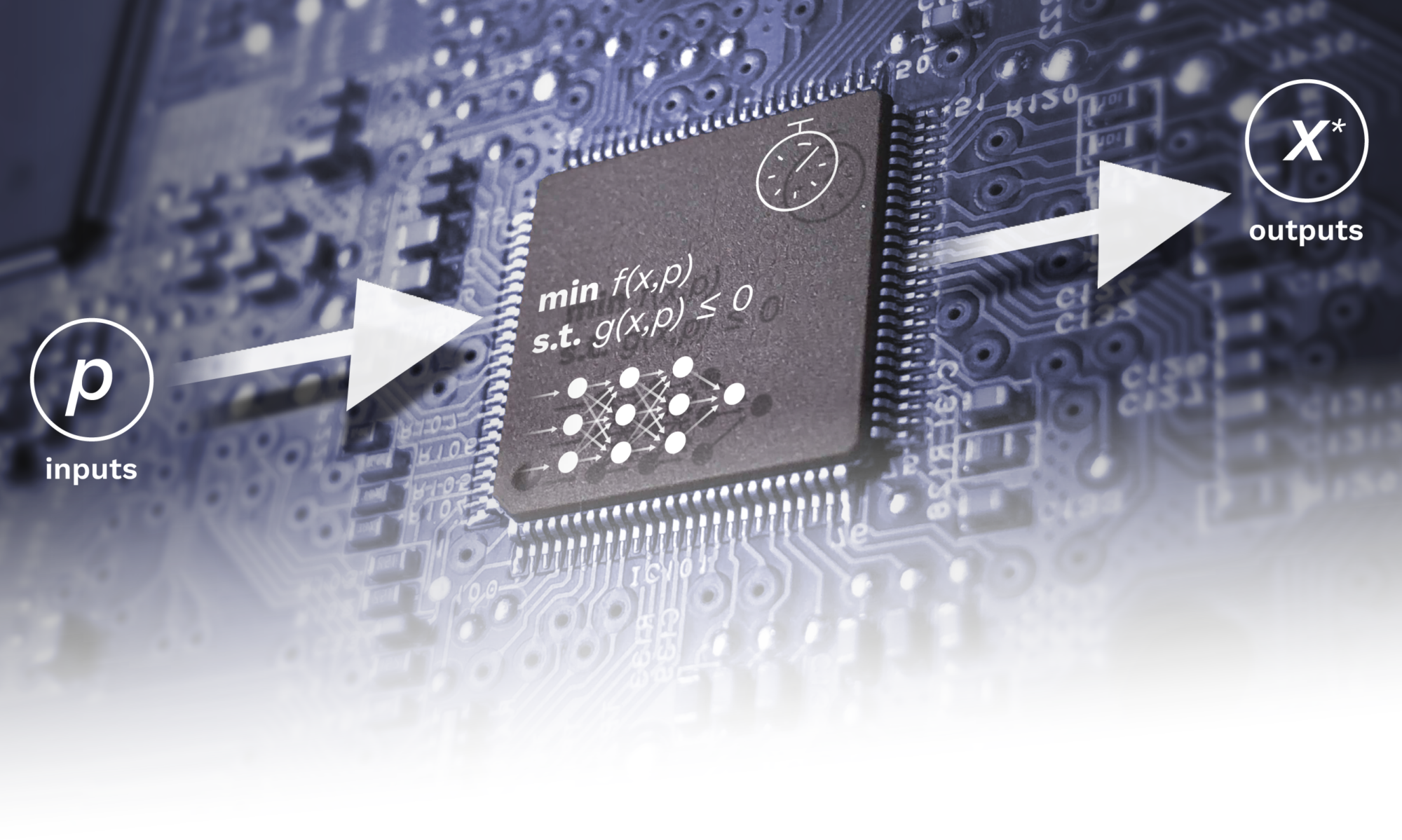

The next generation of highly automated, interconnected, and collaborative industrial systems will require solutions able to: (a) monitor in real-time the system and components’ behavior to estimate their conditions and spot possible faults or anomalies, and (b) manage many interacting subsystems and processes operating at different timescales, with a hierarchical topology, subject to constraints and performance requirements. These two tasks are strongly connected, since condition monitoring and fault detection must be fully integrated in the automation and control system. However, the current design approaches lack a systematic way to carry out such integration. To overcome this challenge, Nicolas will develop a design methodology for automation and control systems where learning-based solutions for condition monitoring, fault detection and recovery are implemented at multiple levels and time-scales in complex hierarchical control systems, and seamlessly integrated with optimization-based decision and control algorithms. The idea is to develop a high-level model predictive controller, running at slower frequency, that coordinates plant-wide operation and monitor its status using learning-based approaches. At lower layers, local controllers will exploit embedded learning and optimization to regulate single processes, monitor them and learn on-line their performance and conditions, implementing the directives received from the higher layers and sending them a feedback about the local status. Based on the overall feedback received from the lower levels, the high-level controller will readjust plant operation with the goal to maximize performance while guaranteeing safety and reliability.